Downloads

Key requirements

Floor and roof drains are plumbing fixtures.They must be trapped, vented and tied to the building sanitary system or storm water drainage system according to AS 3500.

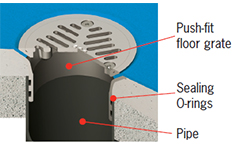

ACO Wexel comprises stainless steel floor grates, available both with and without cast iron bodies, for either a push-fit or a deep body connection.

The cast iron bodies are available in a number of options:

- Adjustable height tops to suit the finished floor level

- Clamp rings and puddle flanges to accommodate the waterproof membrane

- Bucket traps and other variants

The assembly of pipe joints is quick and easy for these units. The outlet is sealed against the inside of the pipe.

Make sure that correct O-ring seal is fitted in place on push-in body to suit either PVC or HDPE pipe.

Make sure that correct O-ring seal is fitted in place on push-in body to suit either PVC or HDPE pipe.

- Red O-rings supplied are for HDPE pipe.

- Black O-rings supplied are for PVC pipe.- Make sure the cut end of the pipe is clean and free of burrs and rough edges- this will make fitment easier and eliminate damage to seals during fitment.

- Apply a light application of lubricant to the seal and the pipe end, making sure mating ends of pipes and fittings are clean and free from contamination.

- Push-fit body into pipe. Use some rotational movement to right and left as pipes come together.

Installation Files:

| Range | Grate | Screed Floor | Vinyl Floor | Tile Floor | ||

|---|---|---|---|---|---|---|

| Push-Fit | Round | |||||

| Push-Fit | Round | |||||

| Push-Fit | Square | |||||

| Push-Fit | Round | |||||

| Push-Fit | Round | |||||

| Push-Fit | Square | |||||

Accommodating vinyl floors:

ACO Wexel push-in bodies and grate assemblies have the option to accommodate vinyl flooring by means of a clamping grate and flange. This creates a water tight seal between vinyl floor and clamp. Care must be taken when the vinyl is cut so that it can be securely clamped and not protrude into the open space beneath where it can restrict flow.

ACO Wexel push-in bodies and grate assemblies have the option to accommodate vinyl flooring by means of a clamping grate and flange. This creates a water tight seal between vinyl floor and clamp. Care must be taken when the vinyl is cut so that it can be securely clamped and not protrude into the open space beneath where it can restrict flow.

Key requirements

Floor and roof drains are plumbing fixtures.They must be trapped, vented and tied to the building sanitary system or storm water drainage system according to AS 3500.

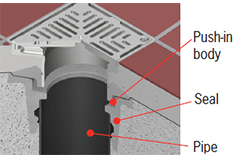

ACO Wexel comprises stainless steel floor grates, available both with and without cast iron bodies, for either a push-fit or a deep body connection.

The cast iron bodies are available in a number of options:

- Adjustable height tops to suit the finished floor level

- Clamp rings and puddle flanges to accommodate the waterproof membrane

- Bucket traps and other variants

The assembly of these units is quick and easy. The outlet is sealed against the outside of the pipe.

The assembly of these units is quick and easy. The outlet is sealed against the outside of the pipe.

- Make sure the cut end of the pipe is clean and free of burrs and rough edges- this will make fitment easier and eliminate damage to seals during fitment.

- Apply a light application of lubricant to the seal and the pipe end, making sure mating ends of pipes and fittings are clean and free from contamination.

- Push-fit body into pipe. Use some rotational movement to right and left as pipes come together.

Installation files:

| Range | Grate | Screed Floor | Vinyl Floor | Tile Floor | |||

|---|---|---|---|---|---|---|---|

| Vertical Utility | |||||||

| Vertical short floor drain | Square | ||||||

| Vertical deep floor drain | Round - vinyl | ||||||

| Vertical puddle flange | Contact ACO | ||||||

| Horizontal floor drain | Square | ||||||

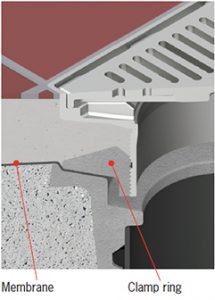

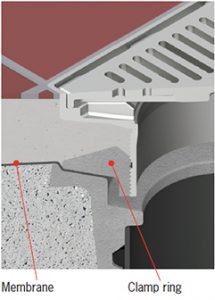

Clamping membranes

Rolled, flexible material membranes can be secured with bolts through a clamp ring. The clamp ring has a drainage function incorporating weep holes.

Grate height adjustment

Grate height adjustment

Adjustable grate assemblies and extension pieces for roof drains can be adjusted to suit a large range of heights. Once fitted, turn either clockwise to lower,or anti-clockwise to raise, until required height is achieved.

Sometimes the unit will need to be cut to achieve the required height.

To cut the unit, use an angle grinder with a cutting disc and cut the riser at the required section between threaded areas.Remove any sharp edges and burrs from cut edges with a file or grinding disc.

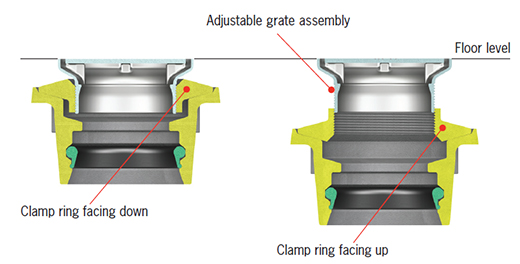

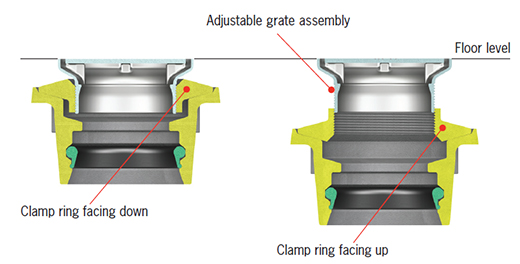

Orientation of clamp ring and fine tuning with thread

Orientation of clamp ring and fine tuning with thread

Changing the clamp ring orientation(down or up) allows for more significant height alterations. Once orientation of the clamp ring is established and fixed in place,install the adjustable grate assembly.

Adjustable grate assemblies have a thread,which allows for easy fine tuning of height adjustment by turning either clockwise to lower, or anti-clockwise to raise, until required height is achieved.

Accommodating vinyl floors:

ACO Wexel push-in bodies and grate assemblies have the option to accommodate vinyl flooring by means of a clamping grate and flange. This creates a water tight seal between vinyl floor and clamp. Care must be taken when the vinyl is cut so that it can be securely clamped and not protrude into the open space beneath where it can restrict flow.

ACO Wexel push-in bodies and grate assemblies have the option to accommodate vinyl flooring by means of a clamping grate and flange. This creates a water tight seal between vinyl floor and clamp. Care must be taken when the vinyl is cut so that it can be securely clamped and not protrude into the open space beneath where it can restrict flow.

Key requirements

Floor and roof drains are plumbing fixtures.They must be trapped, vented and tied to the building sanitary system or storm water drainage system according to AS 3500.

ACO Wexel comprises stainless steel floor grates, available both with and without cast iron bodies, for either a push-fit or a deep body connection.

The cast iron bodies are available in a number of options:

- Adjustable height tops to suit the finished floor level

- Clamp rings and puddle flanges to accommodate the waterproof membrane

- Bucket traps and other variants

Installation files:

| Range | Grate | ||

|---|---|---|---|

| Roof Drain | Flat Grate | ||

| Roof Drain | Dome Grate |

Clamping membranes

Rolled, flexible material membranes can be secured with bolts through a clamp ring. The clamp ring has a drainage function incorporating weep holes.

Grate height adjustment

Grate height adjustment

Adjustable grate assemblies and extension pieces for roof drains can be adjusted to suit a large range of heights. Once fitted, turn either clockwise to lower,or anti-clockwise to raise, until required height is achieved.

Sometimes the unit will need to be cut to achieve the required height.

To cut the unit, use an angle grinder with a cutting disc and cut the riser at the required section between threaded areas.Remove any sharp edges and burrs from cut edges with a file or grinding disc.

Orientation of clamp ring and fine tuning with thread

Orientation of clamp ring and fine tuning with thread

Changing the clamp ring orientation(down or up) allows for more significant height alterations. Once orientation of the clamp ring is established and fixed in place,install the adjustable grate assembly.

Adjustable grate assemblies have a thread,which allows for easy fine tuning of height adjustment by turning either clockwise to lower, or anti-clockwise to raise, until required height is achieved.