Project Planning

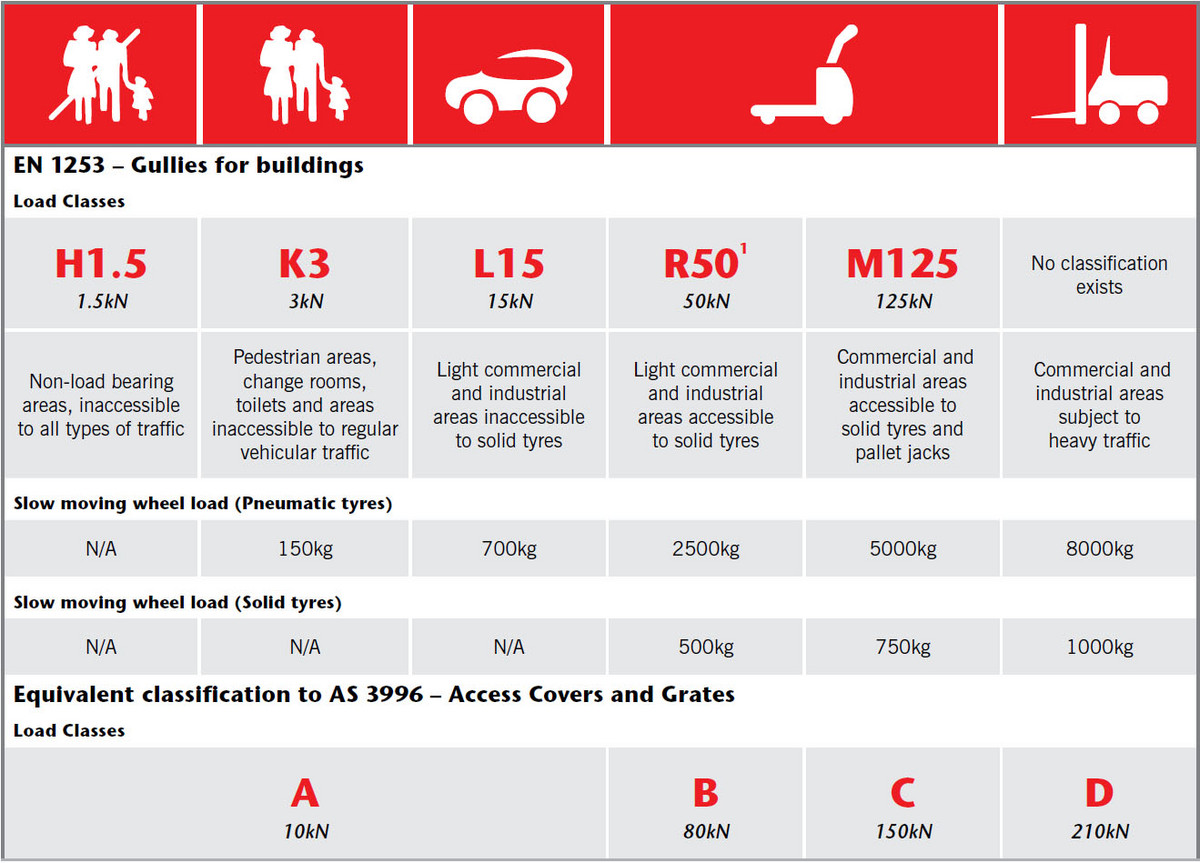

There is no Australian Standard that governs the performance of floor gullies. ACO believes that EN 1253, specifically written to regulate these types of products, is the most appropriate International Standard.

EN 1253 – Gullies for buildings 1. Scope

‘This Standard classifies gullies, gives guidance for places of installation and specifies requirements for construction,design, performance and marking of factory gullies, irrespective of material,for use in drainage systems operating under gravity including siphonic systems.’

The table below is created to give designers,installers and users assistance in selecting the correct product.The table is based on loadings outlined in EN 1253 and is cross referenced with AS 3996 – Access Covers and Grates,the most relevant Australian Standard for load classifications. ACO has gained NATA accreditation (No.15193) for its testing laboratory and can provide test reports to EN 1253.

Standards only give an objective means for comparing products. There are a number of key factors affecting a product’s resistance to load and additional consideration must be given to:

- Type of traffic: Consider the weight of loads being carried, for example forklifts, trolleys and trucks.

- Wheel type: Solid tyres exert more stress through smaller contact areas than pneumatic tyres, so a heavier duty grate may be required. Note, laden trolleys can intensify the load.

- Frequency and speed of traffic: More frequent and faster traffic can intensify the load.

- Position of gully: If the product is positioned where traffic will be turning or braking, or if it is installed at the bottom of a ramp, the gully will be subjected to extreme forces.

1 Draft prEN 1253

Note: For higher load classes contact ACO.

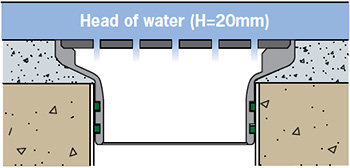

Water flow is restricted by the open area of grate. For the ACO Wexel range, there is no further reduction of flow from the underlying bodies. The head of water creates pressure and is also part of the calculation.

The table below shows the flow rate based on the diagram shown right.

Note that fixed or removable strainers will reduce the flow rates.

| Part No. | Intake area (mm2) |

Based on 20mm head of water (H) |

Based on 30mm head of water (H) |

Based on 40mm head of water (H) |

Based on 50mm head of water (H) |

|

|---|---|---|---|---|---|---|

|

141855 141856 141857 141958 141858 |

2,404 5,503 4,173 N/A 6,901 |

0.98 2.24 1.70 N/A 2.81 |

1.20 2.74 2.08 N/A 3.44 |

1.38 3.17 2.40 N/A 3.97 |

1.55 3.54 2.69 N/A 4.44 |

|

141859 141860 141861 |

2,919 7,216 13,734 |

1.19 2.94 5.59 |

1.46 3.60 6.85 |

1.68 4.16 7.91 |

1.88 4.65 8.84 |

|

141969 141970 141971 |

5,503 7,216 13,734 |

2.24 2.94 5.59 |

2.74 3.60 6.85 |

3.17 4.16 7.91 |

3.54 4.65 8.84 |

| Part No. | Intake area (mm2) |

Based on 20mm head of water (H) |

Based on 30mm head of water (H) |

Based on 40mm head of water (H) |

Based on 50mm head of water (H) |

|

|---|---|---|---|---|---|---|

|

141870 141871 141872 141873 |

5,503 11,199 4,173 6,901 |

2.24 4.56 1.70 2.81 |

2.74 5.58 2.08 3.44 |

3.17 6.45 2.40 3.97 |

3.54 7.21 2.69 4.44 |

|

141874 141875 |

7,216 13,734 |

2.94 5.59 |

3.60 6.85 |

4.16 7.91 |

4.16 7.91 |

|

141862 141864 141866 |

2,404 11,199 4,173 |

0.98 4.56 1.70 |

1.20 5.58 2.08 |

1.38 6.45 2.40 |

1.55 7.21 2.69 |

|

141867 | 2,919 | 1.19 | 1.46 | 1.68 | 1.88 |

|

141876 141877 141878 141879 |

5,503 11,199 4,173 6,901 |

2.24 4.56 1.70 2.81 |

2.74 5.58 2.08 3.44 |

3.17 6.45 2.40 3.97 |

3.54 7.21 2.69 4.44 |

|

141880 141881 141882 |

7,216 13,734 28,310 |

2.94 5.59 11.53 |

3.60 6.85 14.12 |

4.16 7.91 16.30 |

4.65 8.84 18.23 |

|

141883 141884 141885 141886 141887 141888 141889 141890 |

5,503 11,199 4,173 6,901 5,503 11,199 4,173 6,901 |

2.24 4.56 1.70 2.81 2.24 4.56 1.70 2.81 |

2.74 5.58 2.08 3.44 2.74 5.58 2.08 3.44 |

3.17 6.45 2.40 3.97 3.17 6.45 2.40 3.97 |

3.54 7.21 2.69 4.44 3.54 7.21 2.69 4.44 |

|

141891 141892 141893 141894 141895 141896 |

7,216 13,734 28,310 7,216 13,734 16,971 |

2.94 5.59 11.53 2.94 5.59 6.91 |

3.60 6.85 14.12 3.60 6.85 8.46 |

4.16 7.91 16.30 4.16 7.91 9.77 |

4.65 8.84 18.23 4.65 8.84 10.93 |

|

141897 141898 141899 141900 141901 |

2,404 5,503 11,199 4,173 6,901 |

0.98 2.24 4.56 1.70 2.81 |

1.20 2.74 5.58 2.08 3.44 |

1.38 3.17 6.45 2.40 3.97 |

1.55 3.54 7.21 2.69 4.44 |

|

141902 141903 141904 |

2,123 7,216 13,734 |

0.86 2.94 5.59 |

1.06 3.60 6.85 |

1.22 4.16 7.91 |

1.37 4.65 8.84 |

| Part No. | Intake area (mm2) |

Based on 20mm head of water (H) |

Based on 30mm head of water (H) |

Based on 40mm head of water (H) |

Based on 50mm head of water (H) |

|

|---|---|---|---|---|---|---|

|

141905 141906 141907 141908 141909 141910 141911 141912 141913 141914 |

15,180 15,858 22,255 15,180 15,858 16,971 15,180 15,858 15,180 15,858 |

6.18 6.46 9.06 6.18 6.46 6.91 6.18 6.46 6.18 6.46 |

7.57 7.91 11.10 7.57 7.91 8.46 7.57 7.91 7.57 7.91 |

8.74 9.13 12.82 8.74 9.13 9.77 8.74 9.13 8.74 9.13 |

9.77 10.21 14.33 9.77 10.21 10.93 9.77 10.21 9.77 10.21 |

ACO Wexel roof and floor drains require minimum maintenance when they have been correctly installed. Scheduled inspections should be carried out to ensure that they continue to perform efficiently.

ACO Wexel roof and floor drains require minimum maintenance when they have been correctly installed. Scheduled inspections should be carried out to ensure that they continue to perform efficiently.

Initial inspection

Once drains have been installed they should be inspected to ensure that all parts are accounted for and correctly fitted. Nuts and bolts need to be tight and secure. Care must be taken around sharp objects (screws etc.) left by other trades, as they may be trodden on. This can cause damage to the surface material and/or waterproof membrane.

Roof drain maintenance

Every flat roof must have an inspection plan. Roof inspections should be carried out on a regular basis, especially in locations where there are nearby trees creating leaf blockage.

Blockages must be cleared immediately to ensure the system does not overflow. Plastic bags will quickly block a drain or grate, whilst airborne grit and fines will silt up gradually and restrict the flow.

Floor drain maintenance

Regular drain cleaning is very important where there is the potential of severe flooding.

Floor drains are an entry point into the sanitary or stormwater drainage system. Waste is often washed down from floors as well as leaves and litter from external pavements. If maintenance is neglected, solid debris will inevitably clog the underlying pipework causing backups.

Drains in commercial kitchens need particular attention, because wastewater generally contains fats, oil and grease.

For applications requiring a more hygienic and durable solution, a stainless steel body and grate is recommended – refer to ACO Gully.

The use of strainer baskets are recommended to prevent debris from reaching pipework and resulting in costly maintenance. Strainer baskets must be cleaned regularly to remove debris and cleaning intervals are determined by the amount of debris present after each cleaning session.

ACO Wexel’s stainless steel floor grates are appropriate for general use in and around buildings including most coastal locations. Clean with soap, warm water rinse and wipe dry. Under no circumstances treat with metal scouring pads, metal scrapers or wire wool as these will contaminate surfaces leaving rust spots.

The table below is based on information gained from material suppliers and published information. Chemical resistance of materials may vary according to the concentration of chemicals used, the presence of other chemicals and other factors such as temperature.

The following information is a general guide only. It is the customer’s responsibility to ensure the suitability of the product for the application. ACO can supply material samples for testing chemical resistance.

| No effect – excellent | |

| Minor effect – good | |

| Moderate effect – fair | |

| Severe effect – not recommended | |

| No data available |

| Chemical | Grade 304 Stainless Steel | Cast Iron | Nitrile Seal |

|---|---|---|---|

| Acetate solvent | |||

| Acetic Acid | |||

| Acetone | |||

| Alcohol (Amyl/Butyl) | |||

| Alcohol (Methyl) | |||

| Aluminium Chloride | |||

| Aluminium Fluoride | |||

| Aluminium Hydroxide | |||

| Ammonia, Liquids | |||

| Ammonia, Nitrate | |||

| Ammonium Carbonate | |||

| Ammonium Hydroxide | |||

| Ammonium Nitrate | |||

| Ammonium Sulphate | |||

| Amyl Alcohol | |||

| Antifreeze | |||

| Asphalt | |||

| Aviation Fuel (JP#, JP4, JP5) | |||

| Barium Carbonate | |||

| Barium Hydroxide | |||

| Beer | |||

| Benzene | |||

| Benzoic Acid | |||

| Benzol | |||

| Boric Acid | |||

| Butter | |||

| Buttermilk | |||

| Butyl Acetate | |||

| Calcium Chloride | |||

| Calcium Hydroxide | |||

| Cane Juice | |||

| Carbon Dioxide (wet) | |||

| Carbonated Water | |||

| Chlorine (Dry) | |||

| Chlorine Water | |||

| Chocolate Syrup | |||

| Cider | |||

| Citric Acid | |||

| Coffee | |||

| Cream | |||

| Detergents | |||

| Diesel Fuel | |||

| Dyes | |||

| Fatty Acids | |||

| Formic Acid | |||

| Fruit Juice | |||

| Fuel Oils | |||

| Grape Juice | |||

| Grease | |||

| Honey | |||

| Hydraulic Oils (Petroleum) | |||

| Hydrofluoric Acid (100%) | |||

| Hydrogen Peroxide | |||

| Hydrogen Sulfide, Aqueous Solution | |||

| Ink | |||

| Lacquers | |||

| Lacquer Thinners | |||

| Lactic Acid | |||

| Lard | |||

| Lubricants | |||

| Mash | |||

| Mayonnaise | |||

| Methyl Acetone | |||

| Milk | |||

| Mustard | |||

| Oils: Analine | |||

| Caster | |||

| Citric | |||

| Coconut | |||

| Corn | |||

| Fuel (1, 2, 3, 5A, 5B, 6) | |||

| Lemon | |||

| Mineral | |||

| Olive | |||

| Oxalic Acid (Cold) | |||

| Paraffin | |||

| Phosphoric Acid (Crude) | |||

| Petroleum | |||

| Potassium Bromide | |||

| Potassium Carbonate | |||

| Potassium Chloride | |||

| Potassium Nitrate | |||

| Rust Inhibitors | |||

| Salad Dressing | |||

| Sea Water | |||

| Silicone | |||

| Soap Solutions | |||

| Sodium Hydroxide/Caustic Soda (20%) | |||

| Sodium Hydroxide/Caustic Soda (50%) | |||

| Sodium Hydroxide/Caustic Soda (80%) | |||

| Sodium Hypochlorite (to 20%) | |||

| Sodium Peroxide | |||

| Soy Sauce | |||

| Starch | |||

| Styrene | |||

| Sugar (Liquids) | |||

| Sulphur Dioxide | |||

| Sulphuric Acid (to 10%) | |||

| Sulphuric Acid (10-75%) | |||

| Sulphuric Acid (75-100%) | |||

| Syrup | |||

| Tomato Juice | |||

| Vegetable Juice | |||

| Vinegar | |||

| Varnish | |||

| Water Distilled, Lab Grade 7 | |||

| Water (Fresh) | |||

| Water (Salt) | |||

| Weed Killers | |||

| Xylene |